How to Identify Abrasive Filaments for Brush Applications

In various industrial and DIY applications, brushes with abrasive filaments play a crucial role in surface preparation, deburring, and polishing. Identifying the correct type of abrasive filament is essential for achieving the desired results.

Here are some effective methods to help you identify abrasive filaments for brush applications.

1. Check Labels

The first and simplest step is to check the labels on the brushes. Most brushes are labeled with important information, including the type of abrasive filament and its grit size. By examining the label, you can easily determine the type and grit size of the filaments.

Additionally, you can measure the diameter of the filaments to get a more precise understanding of their specifications. This method provides a quick and direct way to identify the abrasive filaments.

2. Examine the Roughness of the Filament Surface

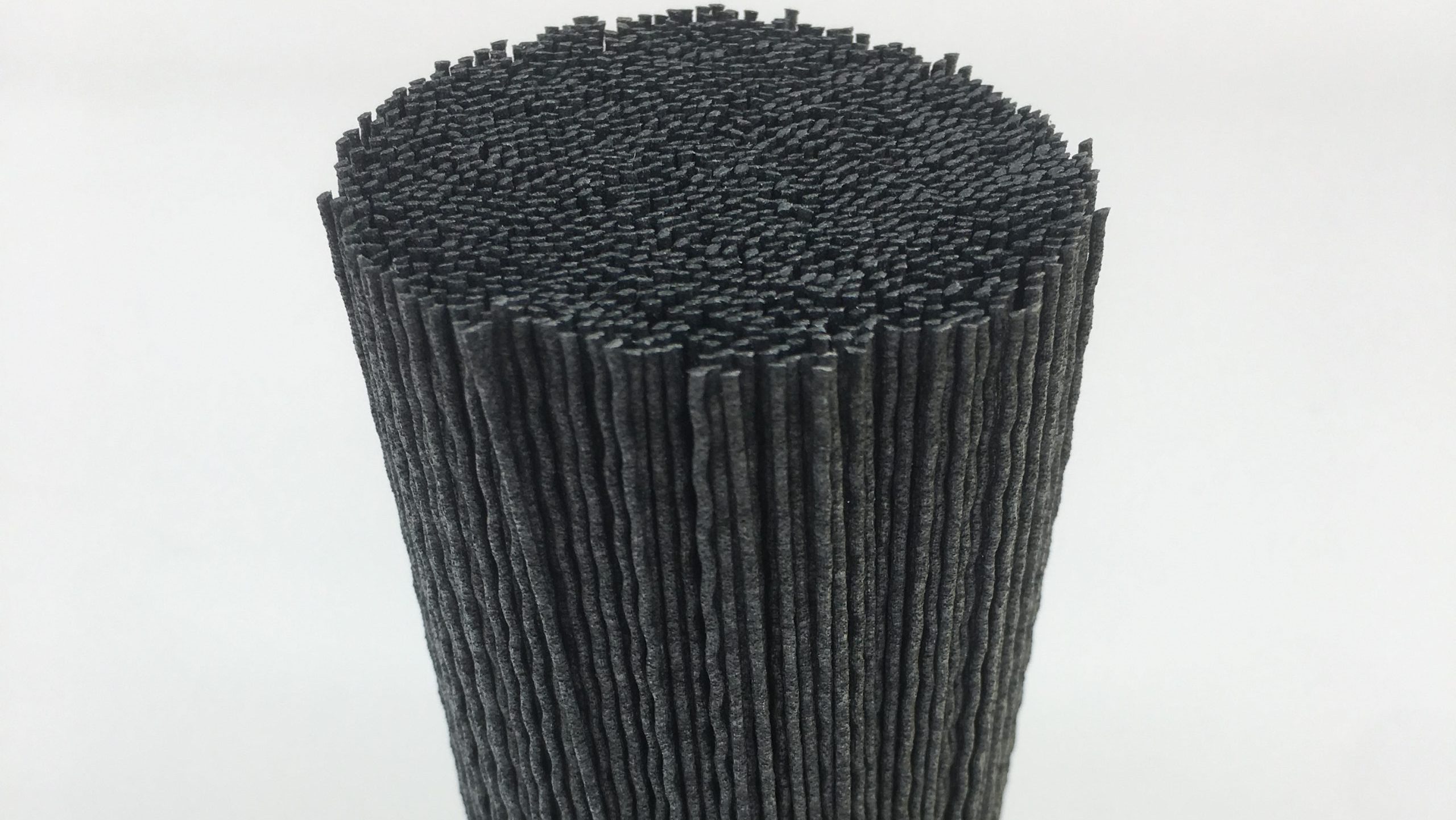

The grit size of abrasive filaments indicates the size of the abrasive particles. Counterintuitively, larger particle sizes are indicated by smaller numbers. To identify the grit size, you can compare the sample filaments with a reference catalog. Pay close attention to the roughness and transparency of the filaments. By doing so, you can make a more accurate determination of the grit size. This method requires a keen eye and some experience but is highly effective.

3. Check the Color

Some abrasive filaments, such as gray black (SIC) and brown (AIO), retain their natural colors without any dyes. For undyed abrasive filaments of the same diameter, the color can vary depending on the grit size. Therefore, checking the color can be a helpful indicator in identifying the grit size of undyed filaments. For example, finer grit sizes may appear lighter in color, while coarser grit sizes may have a darker hue. This visual inspection can provide valuable clues.

4. Clean Samples for Analysis

If you are unable to identify the type of abrasive filament through the above methods, consider sending a clean sample for analysis. Ensure that the sample is free from any contaminants or damage, as used or old samples may not provide accurate information. Our engineers can analyze the clean sample and help you identify the suitable filament type and specifications. This step is particularly important when dealing with specialized or custom-made filaments.

5. Leverage Industry Experience

Each industry has its own set of commonly used abrasive filaments that have been validated through experience. Research the current practices and standards in your industry to identify the typical abrasive filaments used. By understanding the industry’s best practices, you can make informed decisions when selecting the appropriate filaments for your brush applications. This knowledge can save time and ensure optimal performance.

6. Trial and Selection Based on Application

Another practical approach is to base your selection on the roughness of the working surface. For instance, if you are dealing with burrs greater than 75um, you might typically use #180-#240 grit filaments. For burrs between 50um and 75um, #240-#320 grit filaments are often suitable. For finer burrs less than 50um, #320-#500 grit filaments are commonly used. This trial and error method, combined with practical experience, can help you find the most effective abrasive filament for your specific needs.

7. Customize Abrasive Filaments

In some cases, standard abrasive filaments may not meet your specific requirements. In such scenarios, it is possible to customize the filaments. For example, you might increase the diameter to enhance grinding efficiency without compromising precision, or adjust the grit size to improve performance. Customization allows you to tailor the filaments to your unique application, ensuring the best possible results.

In conclusion, identifying the correct abrasive filaments for brush applications involves a combination of methods, including checking labels, examining surface roughness, analyzing colors, and leveraging industry experience. By following these guidelines, you can ensure that you select the most suitable abrasive filaments for your specific needs, leading to improved efficiency and better results in your projects.